29 July

2021

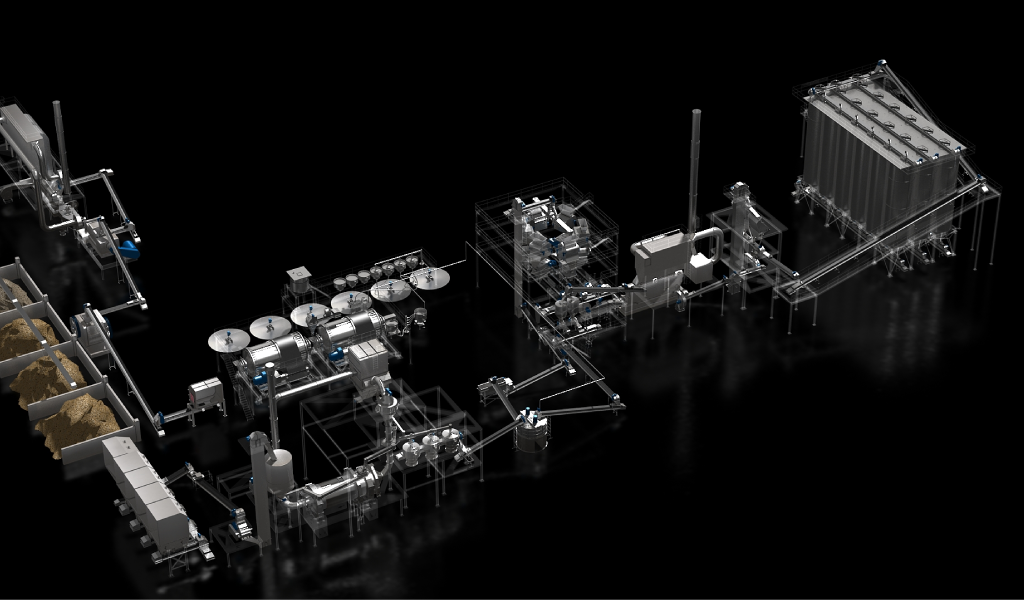

MIGRATECH 4.0

An evolution of Migratech technology, the flexibility of Migratech 4.0 allows using different system design solutions according to the properties of the raw materials and the qualities or typologies of the finished product. The choice of the optimal system configuration is guided by the maximum energy saving obtainable; the selection criteria determine the most appropriate technology in relation to the operation of a wet system.

You might also be interested in

KIT NATURAE BY LB

4 April 2024

The new Kit Naturae comes from LB research for beautiful, high-quality porcelain stoneware, inspired by nature. Naturae is the result of LB’s target to develop a technology capable of reproducing natural aesthetic effects, overcoming the technical limits of materials such as marble and stone. Naturae technology is able to create full-body products with high-impact aesthetic […]

LB AT THE TECHNICAL INSTITUTE FERRARI OF MARANELLO

14 March 2024

On Wednesday 13 March at the Technical Institute Ferrari in Maranello, our HR manager Luigi Fedele and our component department production manager Fabrizio Bonucchi presented the LB group to the students of the fifth classes, “Mechanics-mechatronics” and “Vehicle construction” courses. During the event, a general overview of the group was provided, then going deep into […]

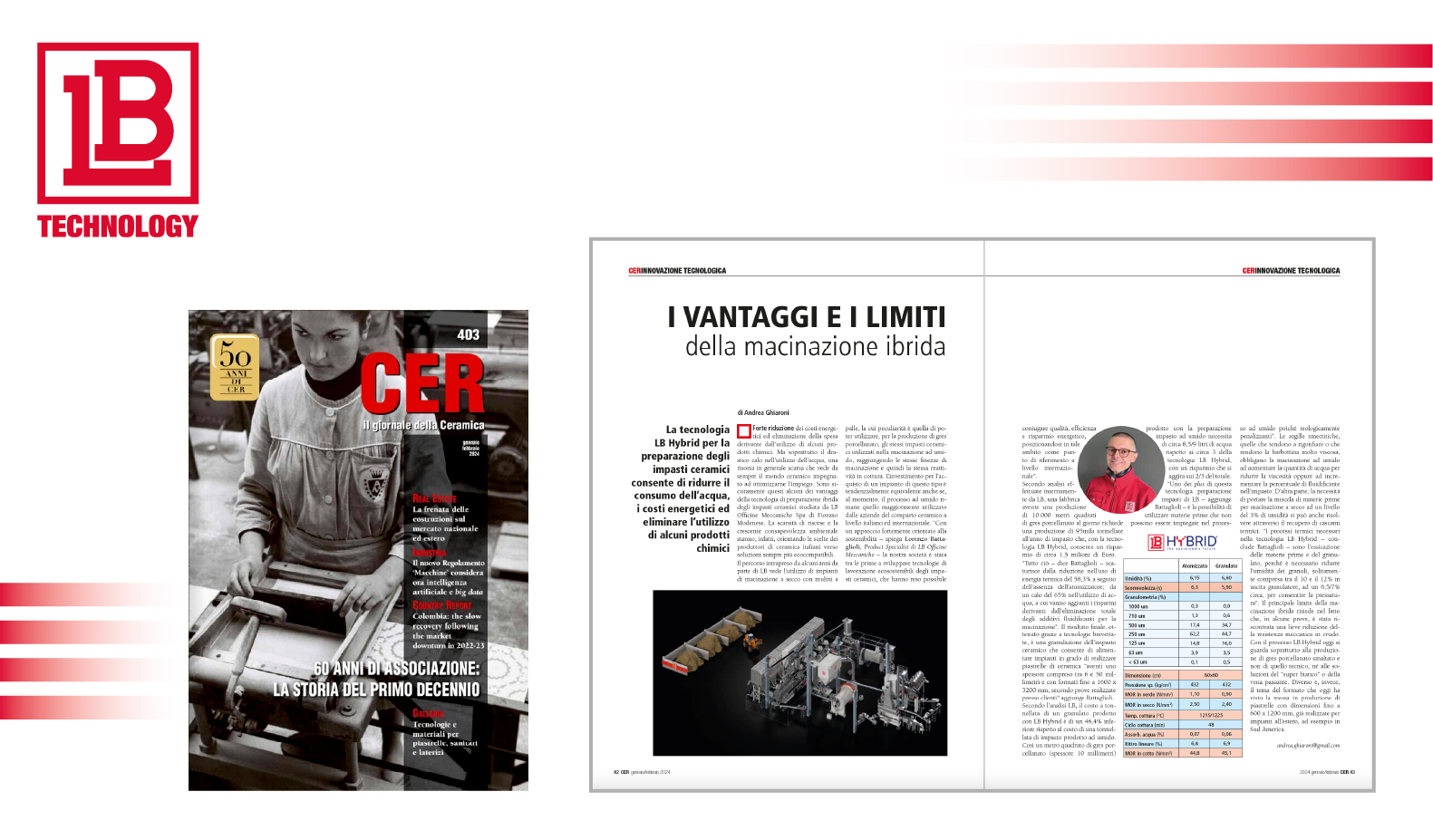

LB HYBRID – ARTICLE ON MAGAZINE CER 403/2024

12 March 2024

We share the interview with @Lorenzo Battaglioli, LB Product Specialist, published on CER 403. In the interview, our Lorenzo Battaglioli talks about the LB Hybrid technology, explaining its advantages such as the reduction of water consumption and energy costs. For further information, read here

NEW SUPPLY OF EASY COLOR BOOST BY LB FOR FEEDING LINE OF LARGE SLABS, CLIENT PARADYZ (POLAND)

5 March 2024

A new contract was recently signed between LB and the Polish company Paradyz for the supply of a tower for mass coloring of spray-dried powders with Easy Color Boost. This LB technology allows the spray-dried product to be colored in real time while feeding the line; it offers excellent production flexibility and simplifies the plant’s […]

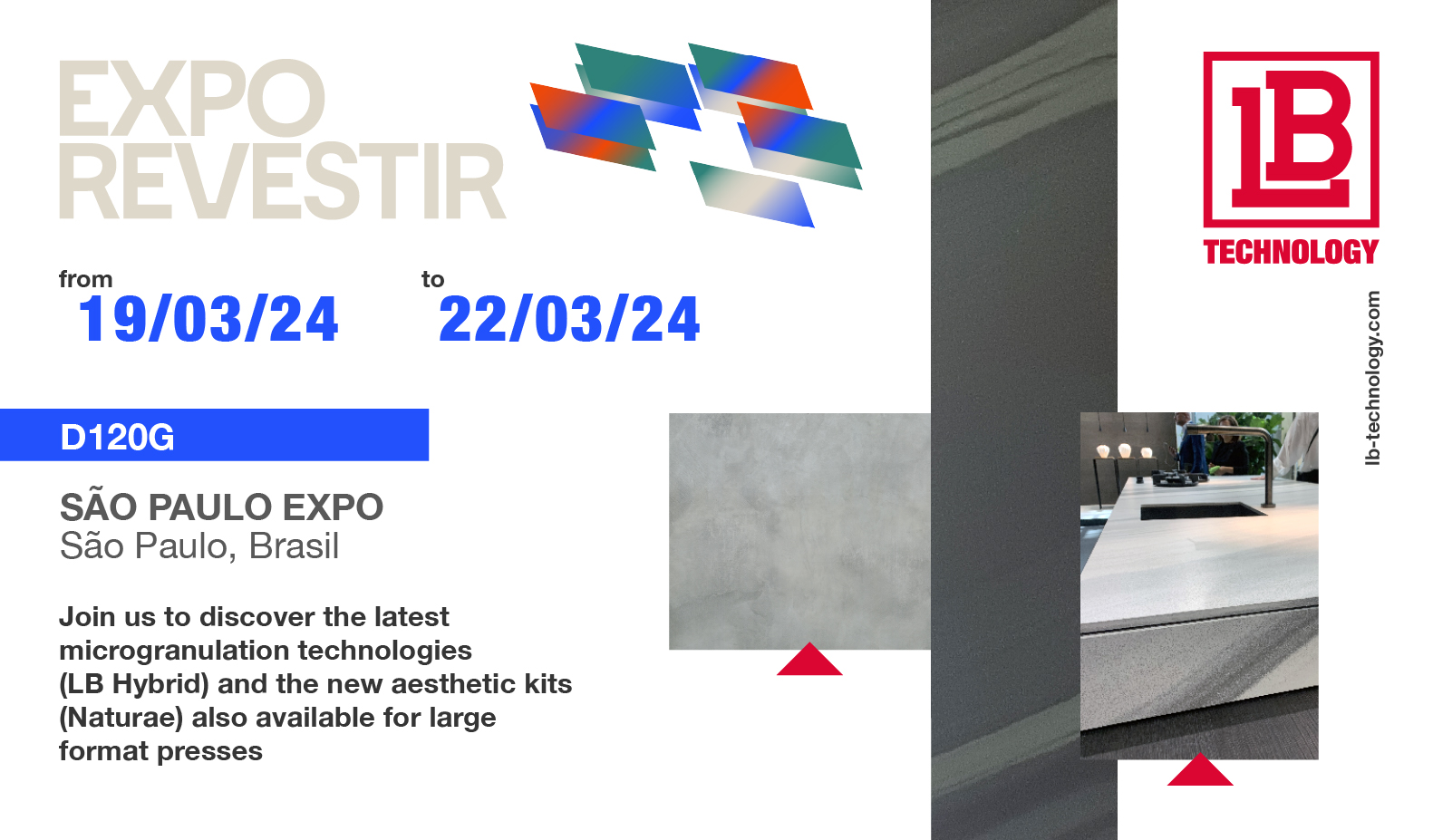

LB AT REVESTIR 2024

7 February 2024

We look forward to your visit at São Paulo Expo Exhibition & Convention Center March 19th to 22nd 2024! Join us to discover LB Hybrid and the newest aesthetic kit Naturae, also available for large format presses.