MICROGRANULATION MIGRATECH

Microgranulation

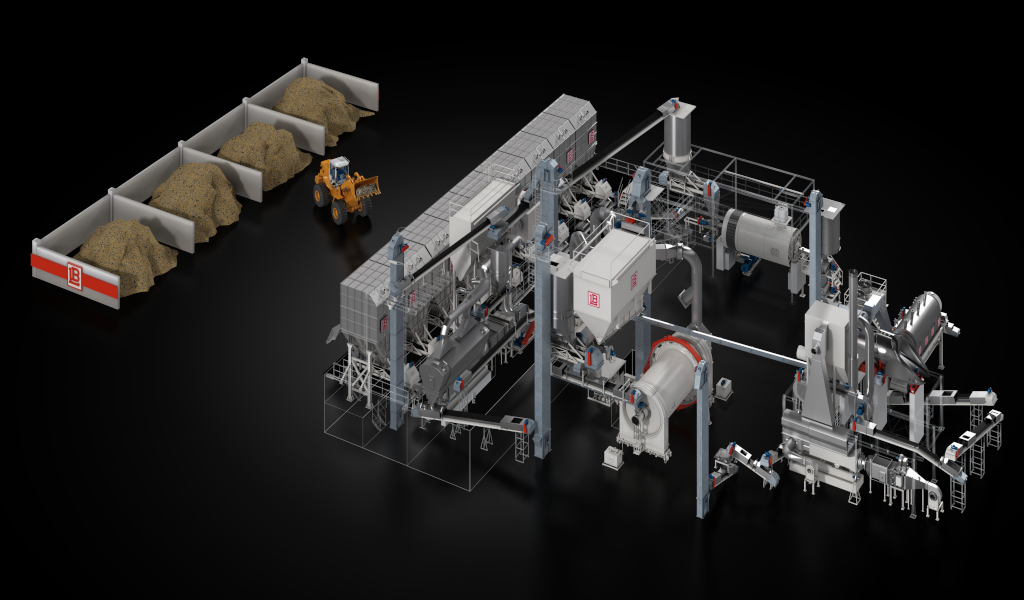

Innovative LB technologies for dry milling with microgranulation

The MIGRATECH technology combines dry grinding with microgranulation: with MIGRATECH, it is it possible to obtain a body that has good smoothness and is easy to de-aerate during the pressing stage, ensuring an even compaction of the ceramic product. The high quality achieved by means of the MIGRATECH technology can be compared to the quality of wet milling processes with spray-drier and allows the creation of large formats.

WHY CHOOSE MICROGRANULATION MIGRATECH

– reduced environmental impact

– average return on investment in 12/18 months

– less voluminous production layout

– lower costs of operation and maintenance.

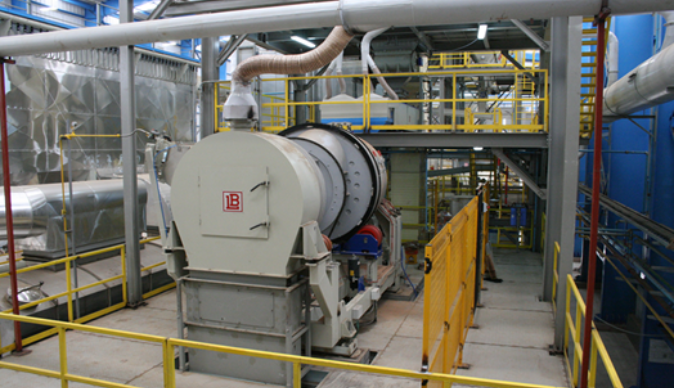

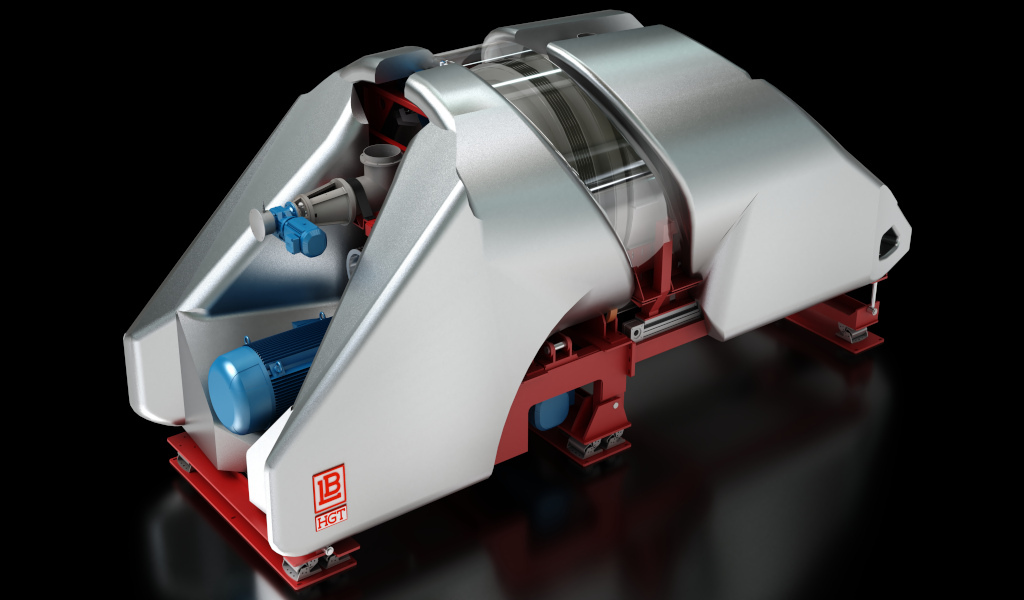

MICROGRANULATION LB HYBRID

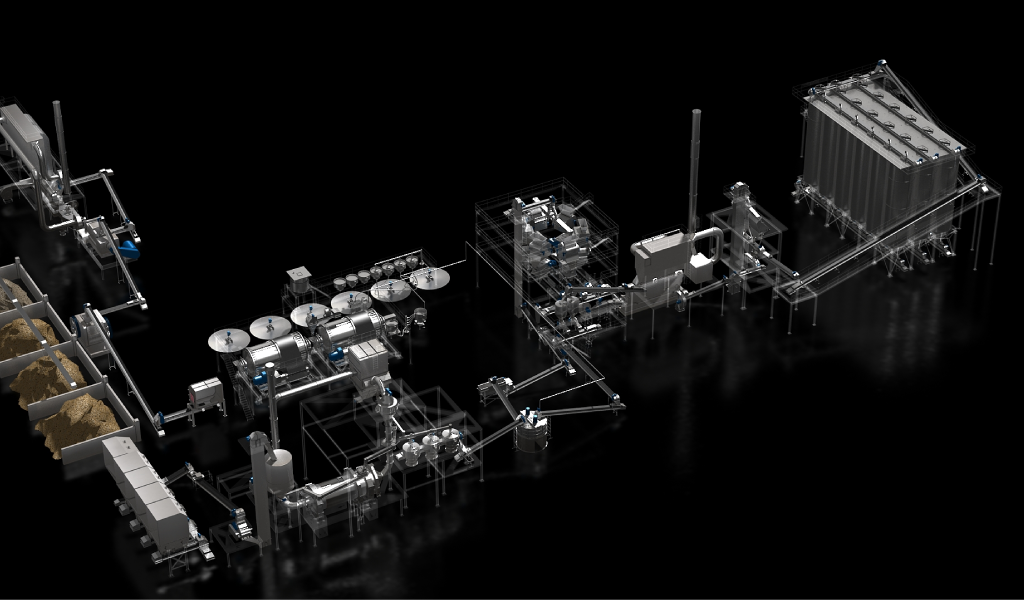

The LB Hybrid technology combines dry grinding, wet grinding and microgranulation with the new granulator HGT. The patented hybrid solution was designed to ensure maximum flexibility, adapting to every manufacturer’s need with the final aim of energy saving and eco-sustainability. It is the best solution to optimize production costs.

WHY CHOOSE LB HYBRID

-65% Thermal energy

-70% Water

-65% CO2 in the atmosphere

-Possibility to be included in existing traditional technology plant

OUR PROCESS

The hybrid solution has been designed to optimize production costs; in this patented technology, dry grinding and wet grinding coexist. In the hybrid technology, microgranulation occurs by nucleation of dry ground powder when the slip is injected into the granulator (with appropriate nozzles) under the correct pressure, in certain powder slip proportions. Both parts must have the same composition. Granulation takes place inside the continuous microgranulator HGT (Hybrid Granulation Technology). Subsequently, the micro-granulate is sent to a fluidised bed drying line (EVF) and returned to moisture values suitable for pressing.

Innovative dry milling technology with microgranulation, which has made possible to combine quality, efficiency and energy saving in ceramic bodies, setting new quality standards compared to the traditional systems and effectively opening a new frontier for large formats with dry milled ceramic bodies.

An evolution of Migratech technology, the flexibility of Migratech 4.0 allows using different system design solutions according to the properties of the raw materials and the qualities or typologies of the finished product. The choice of the optimal system configuration is guided by the maximum energy saving obtainable; the selection criteria determine the most appropriate technology in relation to the operation of a wet system.

CONTACT US AND DOWNLOAD THE PRODUCT SHEETS