POWDER COLOURING

Powder colouring

Dry-colouring systems for ceramic powder

Dry-colouring of ceramic powder is one of the most significant technological innovations in recent years and has had a major impact on the production process of porcelain tiles.

LB was the first company to invent the dry-colouring system of ceramic powder, by means of the Easy Color solutions.

WHY CHOOSE LB

First company to invent the dry-colouring system of ceramic powder which, together with the press dual loading system, is the technological innovation that changed the production process of porcelain tiles. Savings and efficiency when managing power storage and feeding. The Easy Color solutions – System and Boost – developed and patented by LB, allow energy saving of up to 50%, lower mechanical stress since the granulometric curve and mechanical resistance are maintained, better colour performance due to a more appropriate distribution of colouring oxides on the surface to be coloured.

OUR PROCESS

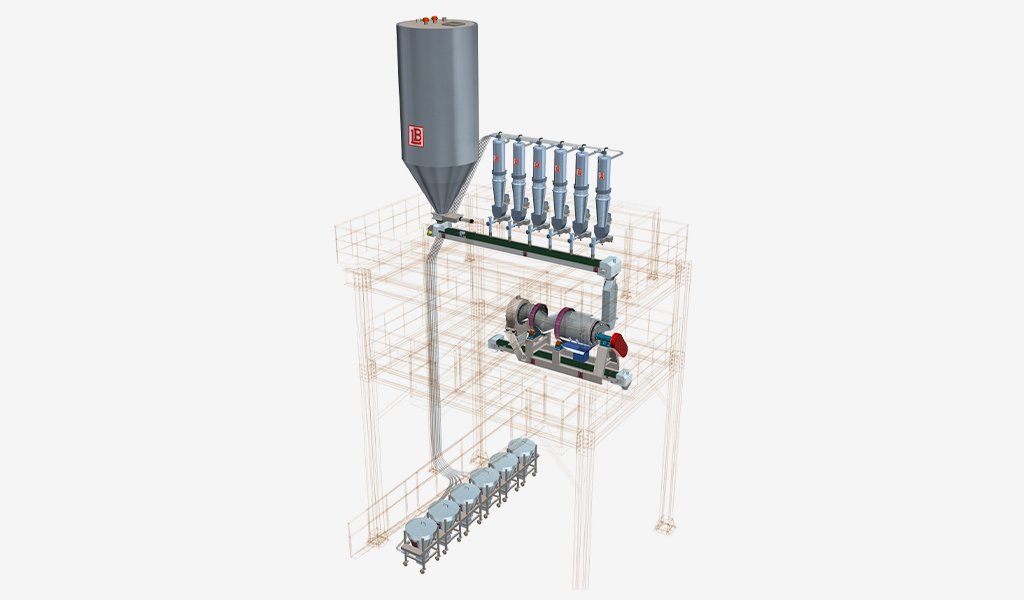

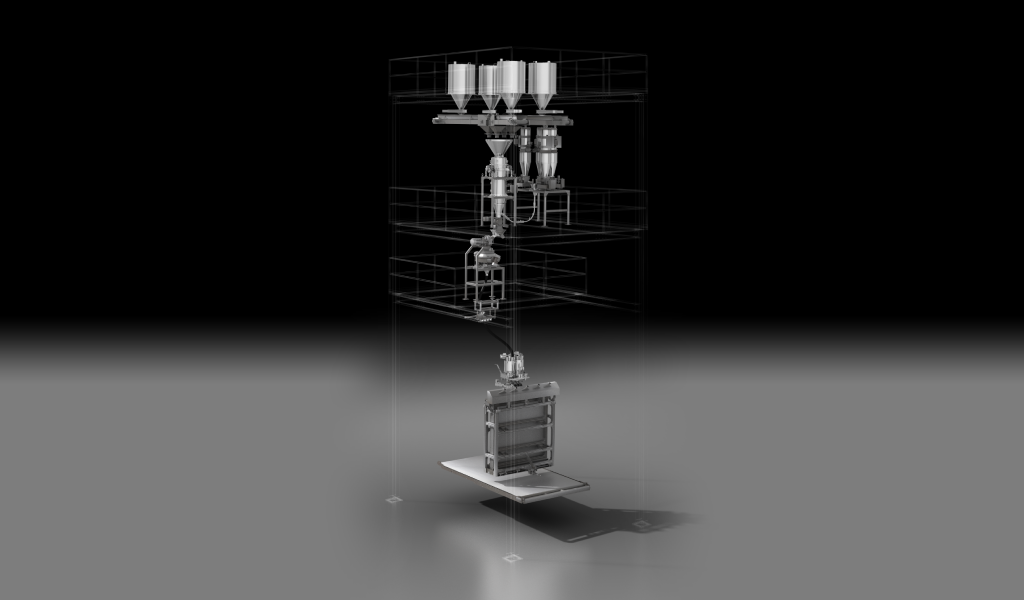

FREESTILE is a revolutionary system to prepare powder that simplifies and reduces ceramic production layouts and increases effectiveness, flexibility and colour variability when producing fine porcelain stoneware, either technical or enamelled. The Freestile process includes the innovative EASY COLOR BOOST technology (patented by LB) to dry-colour ceramic body as well as the revolutionary DIVARIO press feeding system.

OUR MACHINES

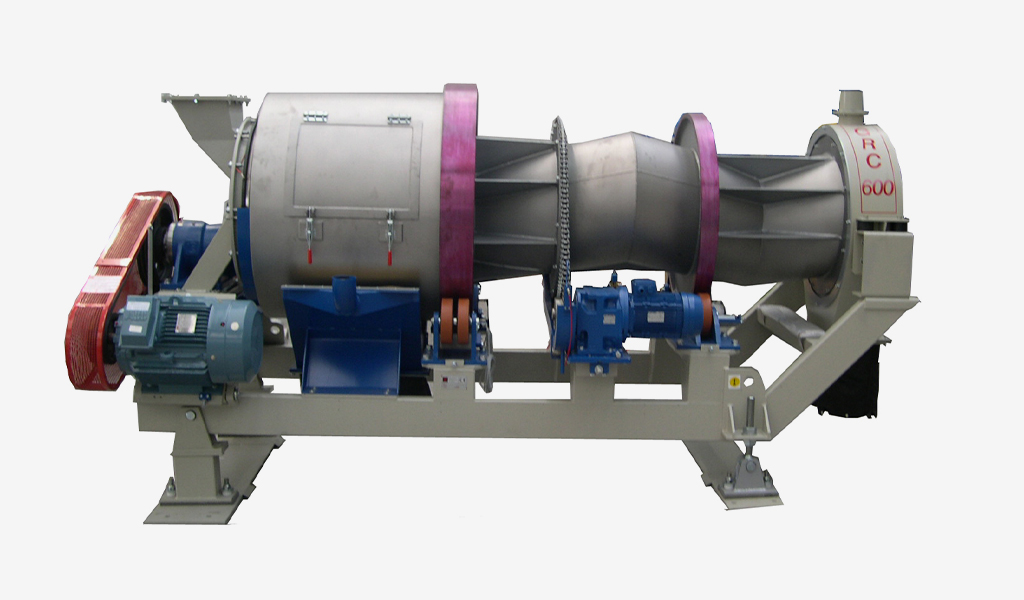

EASY COLOR BOOST is the new LB patent for dry colouring ceramic bodies. It is the evolution of Easy Color System technology, that has led the field of dry colouring for over fifteen years. It simplifies configuration of production plant, drastically reduces energy consumption and the time needed for maintenance and cleaning. It also reduces mechanical stress on the coloured mixture. Furthermore, EASY COLOR BOOST increases the intensity of colour and the colour range to create ceramic products of superior quality.

CONTACT US AND DOWNLOAD THE PRODUCT SHEETS