GRANULATION

Granulation

Systems for dry and wet granulation of powdered materials

LB designs and manufactures systems for powder granulation used by different industrial sectors. The granulation process helps powder to slide more easily, so it is compatible with operating processes and use of the finished product according to the customer’s requirements. Granulation can be performed dry or wet, both in the ceramic sector and other sectors, such as fertilisers and pet food.

WHY CHOOSE LB

Full know-how and maximum efficiency in managing the process. Maximum customisation of solutions according to the requirements for use of the finished product.

OUR MACHINES

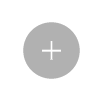

HGT is the new continuous operation horizontal granulator; reliable and versatile, itcan be usedfor various productions in the chemical, mining, ceramic and other sectors. The machine is composed by a rotating mobile body, which is installed on a solid static base. The loading of the material that has to be treated, takes place inside a cylindric-shaped container, seat of a special intensifying bar; the binding liquid (water or binder) is also introduced inside the cylindrical container thanks to the spray nozzles housed on the bar. The adjustments of the speed of the cylinder, of the intensifying bar and of the quantity of binder, as well as of the inclination of the machine, are managed by a (smart) software, and allow to obtain granules of various particle sizes and with variable humidity. The rotating container of the HGT granulator is made of internally polished AISI 304 stainless steel, while the base is made of painted carbon steel. The machine is produced in various models, based on the features of the material to be treated and on the required productivity.

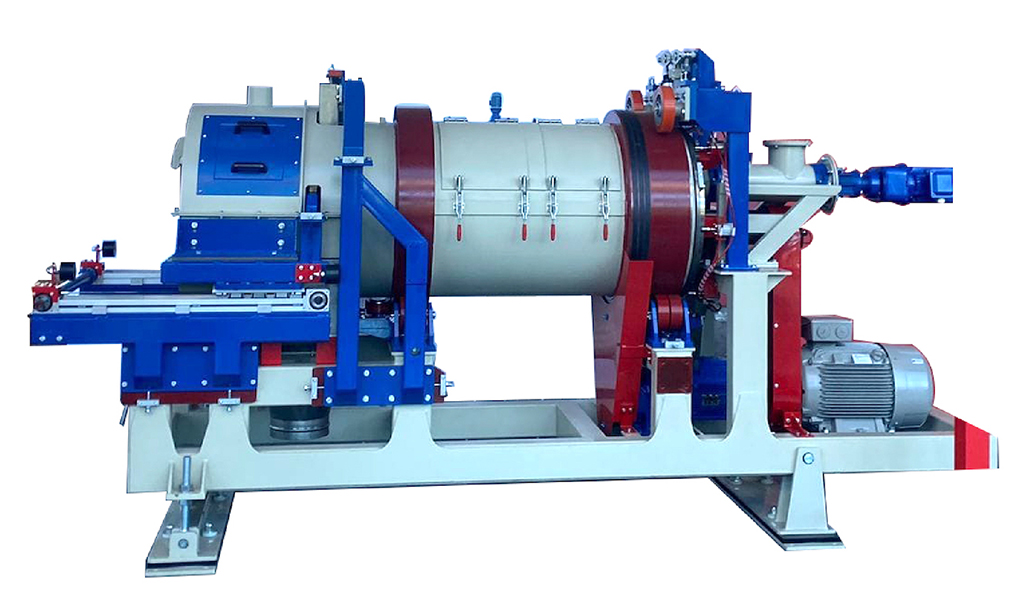

GRC is a continuous horizontal granulator; the machine is extremely versatile and reliable and is used for various manufacturing activities in the chemical, mining, ceramic and other industrial sectors. GRC granulator is made up of a rotating movable body installed on a static solid base. The rotating body is divided into two separate parts. The first section of the machine, where material is loaded, consists of a cylindrical barrel complete with a special intensifyingbar. Also the binding liquid is inserted in this first section by means of spraying nozzles. The second part of the machine has a peculiar sinusoidal shape; the unloading mouth is located at the end of this section. The rotating body of GRC granulator is made of internally polished AISI 304 stainless steel, and the supporting base is in carbon steel. GRC is produced in various models according to the characteristics of the processed material and the required production output.

CONTACT US AND DOWNLOAD THE PRODUCT SHEETS